In the world of supply chain management, staying ahead of the curve is crucial for success. In the YouTube video titled “Supply Chain Talk: Data-Driven Forecasts, 3D Printing, and NRF’s Big Shift,” Sarah Barn Humphrey delves into a variety of topics that are shaping the future of the industry. From discussing forecast accuracy and the impact of 3D printing in space to exploring the latest insights from NRF, this video promises to provide valuable insights for supply chain professionals. Join us as we analyze the key takeaways from this discussion and uncover the potential implications for the future of supply chain management.

Data-Driven Forecast Accuracy in Supply Chain Management

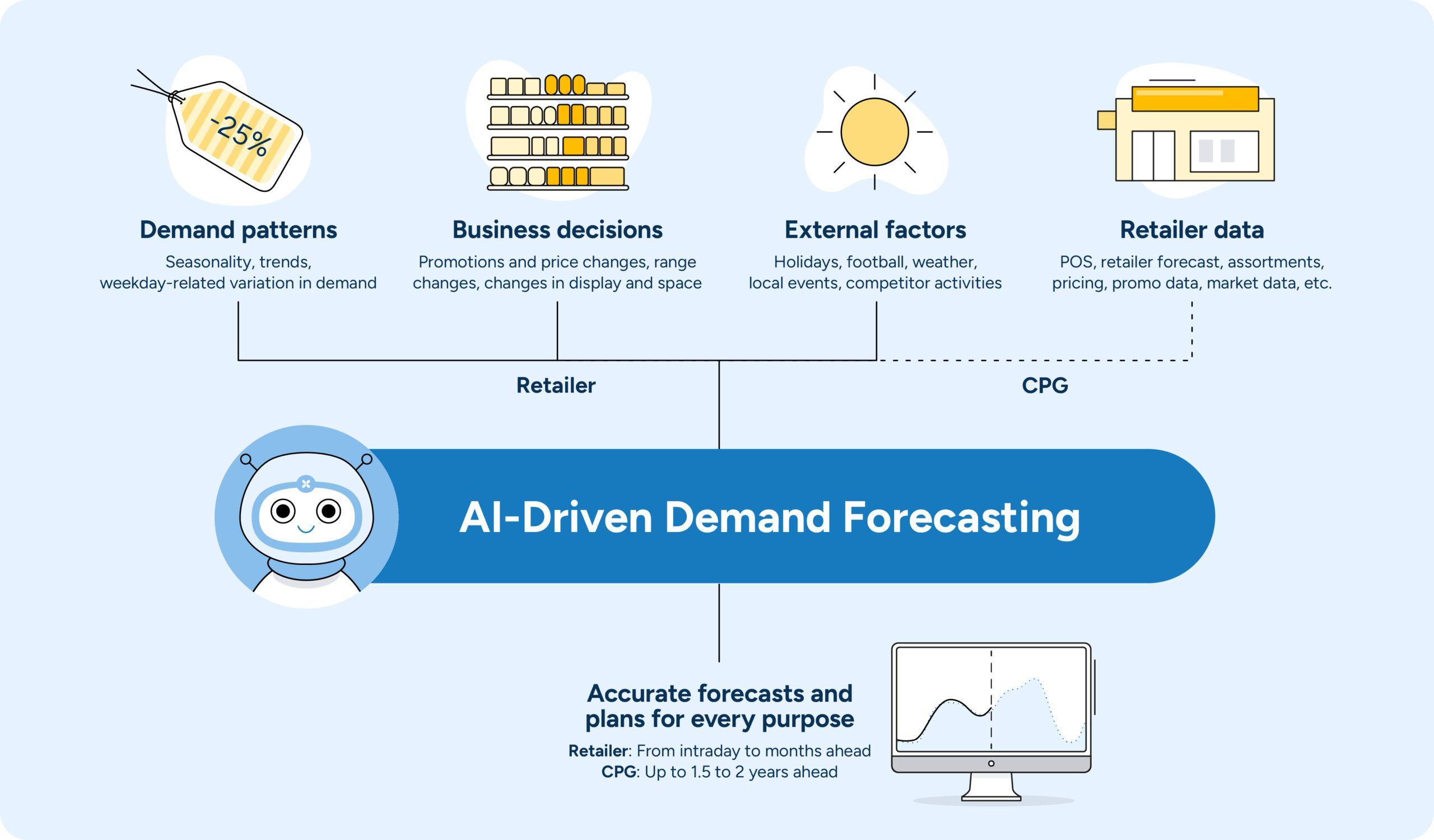

Discussing the importance of data-driven forecast accuracy in supply chain management is crucial in today’s dynamic business environment. With the ever-changing market conditions and customer demands, supply chain experts must leverage data analytics to enhance forecast accuracy for better decision-making processes. By utilizing advanced forecasting techniques and technologies, supply chain professionals can optimize inventory levels, streamline operations, and improve customer satisfaction.

Along with data-driven forecasts, the integration of 3D printing technology in supply chain operations is revolutionizing the industry. This disruptive technology allows for on-demand production, reducing lead times and transportation costs. Supply chain experts need to explore the potential of 3D printing in transforming traditional manufacturing processes and creating more agile supply chains to adapt to market changes swiftly.

Implications of 3D Printing in Supply Chain Operations

In the ever-evolving landscape of supply chain operations, the integration of 3D printing technology has notable implications that cannot be overlooked. as a supply chain expert, it is indeed crucial to understand how this disruptive technology is reshaping traditional manufacturing processes and presenting new opportunities for optimization and innovation. one key advantage of 3D printing in supply chain operations is the ability to create on-demand, customized parts and products, reducing lead times and inventory costs.

Furthermore, the adoption of 3D printing can enhance supply chain resilience by decentralizing production, reducing dependency on overseas suppliers, and mitigating risks associated with disruptions in the global supply chain. Leveraging data-driven forecasts and advanced analytics, supply chain professionals can strategically incorporate 3D printing technology to streamline operations, enhance efficiency, and stay ahead of the competition in today’s dynamic business environment.

NRF’s study Insights and Industry Shifts Recommendations

Discussing NRF’s study insights and industry shifts, the supply chain landscape is experiencing significant transformations. Embracing data-driven forecasts, leveraging the potential of 3D printing, and adapting to NRF’s big shift are crucial considerations for supply chain experts. The evolving dynamics underscore the necessity for agile strategies and proactive responses to stay ahead in the competitive market.

- Data-Driven Forecasts: Utilizing advanced analytics and real-time data to enhance forecast accuracy and optimize supply chain operations.

- 3D Printing Innovation: Integrating 3D printing technology to revolutionize manufacturing processes, reduce lead times, and customize products to meet consumer demands.

- NRF’s Industry Shift: Adapting to NRF’s study findings and recommendations to align with emerging trends, enhance customer experiences, and drive operational efficiency.

In Conclusion

The YouTube video “Supply Chain Talk: Data-Driven Forecasts, 3D Printing, and NRF’s Big Shift” delves into crucial topics shaping the realm of supply chain management. From discussing forecast accuracy and the impact of 3D printing in space to dissecting the latest insights from NRF, the conversation provides valuable insights for industry professionals. As we navigate the ever-evolving landscape of supply chain operations, staying informed and adaptable is key. Stay tuned for more insightful discussions and updates in the world of supply chain management.