Navigating the turbulent skies of today’s supply chain crisis, airlines are reaching impressive new heights of ingenuity to keep their fleets aloft. From scavenging for spare parts in unconventional places to rethinking traditional maintenance strategies, the aviation industry is confronting unprecedented challenges with bold, creative solutions. In this article, we take off on a journey through the ways airlines are adapting to aircraft parts shortages—reshaping their operations to ensure smooth flying, even amid rocky skies.

Supply Chain Disruptions Impacting Airlines

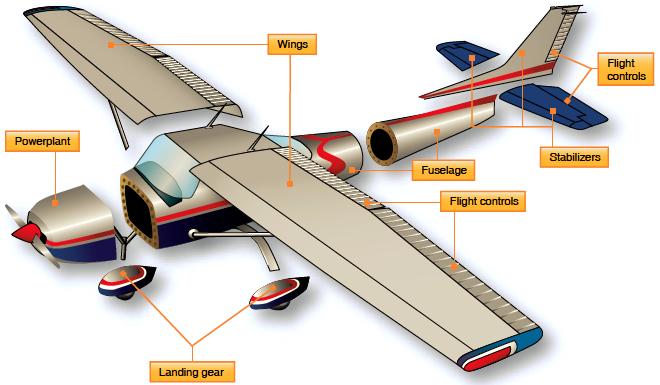

As global supply chain disruptions continue to rattle industries, the aviation sector finds itself particularly vulnerable. Airlines around the world are grappling with critical shortages of essential aircraft components—everything from landing gear and avionics to basic interior parts. These shortages are causing maintenance delays, increased downtime, and in some cases, the outright grounding of aircraft. With schedules on the line and passengers expecting seamless service, airlines are being pushed to rethink the way they manage, source, and maintain their fleets.

To stay airborne, the industry is turning to some remarkably inventive strategies. One of the most promising solutions is 3D printing, which allows airlines and maintenance providers to manufacture certain components on-demand. While not every part can be printed—particularly those requiring high-certification standards—non-critical parts like cabin fixtures or protective covers are increasingly being produced in-house, slashing both wait times and costs.

Another creative tactic is harvesting usable components from retired or decommissioned aircraft, a practice sometimes referred to as “parting out.” These aircraft, instead of being scrapped entirely, are becoming gold mines of serviceable parts. Airlines and MROs (maintenance, repair, and overhaul providers) are salvaging everything from engines to electronic modules, refurbishing them, and putting them back into service with full regulatory compliance.

Innovative Solutions for Aircraft Parts Shortages

Airlines around the globe are grappling with a significant aircraft parts shortage, driven by ongoing supply chain disruptions and global logistics constraints. As these challenges persist, the aviation industry is accelerating its adoption of innovative maintenance strategies to keep aircraft in service and avoid costly groundings. To maintain operational efficiency and minimize delays, airlines are turning to creative, collaborative solutions that are reshaping the way maintenance and repair operations (MRO) are handled.

Collaborative Parts Sharing and Inventory Pooling

One standout solution gaining traction is the collaborative sharing of spare parts between airlines. Instead of working in isolation, carriers are forming strategic partnerships that allow them to pool their parts inventory, share maintenance resources, and tap into a broader network of available components. These airline alliances and interline agreements are especially valuable for accessing hard-to-find or long-lead-time parts, improving fleet availability and reducing aircraft-on-ground (AOG) events.

For example, by sharing access to critical components like avionics units, hydraulic pumps, and landing gear assemblies, partner airlines can significantly cut down on lead times and reduce the financial burden of holding extensive inventories. In some cases, regional MRO hubs are being established to manage and distribute these shared parts more efficiently, streamlining logistics across multiple carriers.

Challenges and Opportunities for the Aviation Industry

The global supply chain crisis has hit the aviation industry hard, especially when it comes to getting the aircraft parts needed to keep planes flying. Airlines are facing delays, higher costs, and even the grounding of aircraft due to shortages of essential components. However, this tough situation is also creating new opportunities for smarter, more flexible ways of working.

1. Turning to Alternative and Aftermarket Suppliers

With many traditional suppliers struggling to meet demand, airlines are looking elsewhere for help. They’re turning to aftermarket parts, refurbished components, and independent suppliers to fill the gap. These sources are helping airlines stay in the air while reducing reliance on a few major manufacturers.

2. Working More Closely with Manufacturers

Airlines are also teaming up with aircraft and parts manufacturers to solve problems together. By sharing data and planning ahead, they’re finding better ways to track parts, speed up deliveries, and avoid delays. This kind of collaboration is proving essential in managing the crisis.

3. Building New Partnerships

To stay ahead, many airlines are forming strategic partnerships with other carriers, repair shops, and logistics companies. By working together, they can share parts, reduce downtime, and improve operations. Technology is also playing a bigger role, with tools like AI and predictive analytics helping airlines manage their parts inventory more efficiently.

The Conclusion

As airlines navigate the turbulent waters of the supply chain crisis, creativity has emerged as a necessary tool in the quest for solutions. From repurposing aircraft parts to exploring new sourcing options, the industry is forging ahead with resilience and innovation. As the global transportation landscape continues to evolve, one thing is clear - the skies may be facing challenges, but the spirit of adaptation is soaring high.