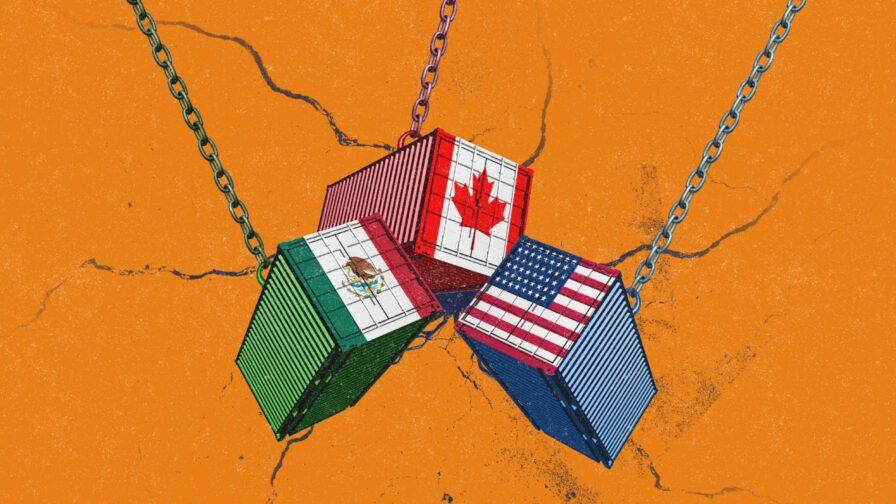

As global trade tensions continue to escalate, the automotive industry is bracing itself for the impact of new tariffs on steel and aluminum. The imposition of these tariffs is expected to drive up production costs for automakers, with potential ripple effects across the entire supply chain. In this article, we will delve into the implications of these tariffs on the auto industry and examine how manufacturers are strategizing to navigate this challenging landscape.

Impact of Tariffs on Steel and Aluminum on Auto Manufacturing Costs

In recent developments, the imposition of tariffs on steel and aluminum imports has sent shockwaves through the auto industry, causing concern among experts and stakeholders. The rising costs of these essential materials are expected to have a significant impact on the manufacturing process and overall expenses within the auto sector. With steel and aluminum being fundamental components in the production of vehicles, the increased tariffs are likely to result in higher production costs.

the automotive industry,already facing challenges such as fluctuating market demands and evolving consumer preferences,is now confronted with the additional burden of elevated material costs. This coudl possibly lead to a ripple effect across the supply chain, affecting various aspects of auto manufacturing, including production schedules, pricing strategies, and profit margins. As companies strive to navigate these uncertain waters, it remains crucial for supply chain professionals to adapt and devise innovative strategies to mitigate the repercussions of these tariffs in an ever-changing global trade landscape.

Potential Challenges Faced by Auto industry Due to Increased Tariffs

Increased tariffs on steel and aluminum are set to pose significant challenges to the auto industry. These tariffs, imposed by the government as a measure to protect domestic industries, are expected to lead to higher production costs for automakers. With steel and aluminum being primary materials in car manufacturing, the industry is highly likely to face increased expenses which could ultimately impact consumer prices and profitability.

Furthermore,the auto industry heavily relies on global supply chains,making it vulnerable to disruptions caused by tariffs and trade wars. These challenges may also result in strained relationships with international suppliers and partners, leading to potential delays in production and distribution. As a supply chain expert, it is crucial for companies in the auto industry to closely monitor these developments and adapt their strategies to navigate the changing landscape of international trade.

Strategies for Mitigating Higher Costs in the Auto Sector

The imposition of tariffs on steel and aluminum is expected to have significant repercussions on the auto industry, leading to higher costs across the supply chain. As a supply chain expert, it is indeed crucial to develop strategies to mitigate these increased expenses and maintain competitive advantages in the market.

One effective approach is to diversify sourcing options by exploring option suppliers or regions less impacted by the tariffs. Additionally, implementing lean practices and optimizing inventory management can help minimize waste and reduce overall costs.Collaborating closely with suppliers to negotiate better pricing and revisiting existing contracts in light of the tariff changes are also essential steps in navigating the challenging landscape of the auto sector in the face of rising costs.

Recommendations for Navigating Tariff-Induced Cost Pressures in the Auto Industry

In the wake of recent tariff policies affecting steel and aluminum, supply chain experts are bracing for the ripple effects that will impact the auto industry. The imposition of tariffs is likely to lead to higher production costs for automakers, ultimately influencing consumer pricing and industry competitiveness. The interconnected nature of global supply chains in the auto sector makes navigating these tariff-induced cost pressures a complex challenge.

- Implementing strategic sourcing tactics to diversify suppliers and mitigate dependence on affected regions.

- Exploring alternative materials or design modifications to adapt to changing cost structures.

| Actions | Impact |

|---|---|

| Redesigning supply chain routes | Reduced transportation costs |

| Renegotiating contracts with suppliers | Potential cost savings |

Moreover,as uncertainties persist,collaboration across the industry and proactive risk management will be key. by monitoring trade developments and enacting agile strategies, companies can strive to remain resilient in the face of economic volatility.

Final Thoughts

the implementation of tariffs on steel and aluminum is anticipated to have a significant impact on the auto industry, leading to higher production costs and potentially affecting both manufacturers and consumers. As the situation continues to evolve, it will be crucial for industry stakeholders to closely monitor developments and adapt their strategies to navigate the challenges presented by these trade policies.Additionally, policymakers and trade experts must continue to assess the broader implications of such tariffs on the global economy and work towards finding enduring solutions that balance trade interests with the needs of domestic industries. The coming months will undoubtedly provide further insight into the lasting effects of these tariffs on the auto industry and the wider economic landscape.