In the intricate web of manufacturing processes, the thread of product traceability can easily become tangled. Unraveling this complexity is crucial to ensure transparency, efficiency, and compliance.In this article, we will explore six innovative ways to tighten the knot of product traceability in manufacturing. from leveraging cutting-edge technology to implementing best practices, these strategies will pave the way for a seamless and accountable production journey.Join us as we delve into the realm of traceability enhancement and discover how it can revolutionize the manufacturing landscape.

Ways to Enhance Product Traceability Systems

Enhancing product traceability systems is crucial in today’s competitive manufacturing landscape. By implementing the right strategies, companies can improve efficiency, reduce risks, and ensure compliance with regulations. Here are some innovative ways to tighten product traceability:

- Implement Blockchain Technology: Utilize blockchain to create a secure and transparent digital ledger for tracking products throughout the supply chain.

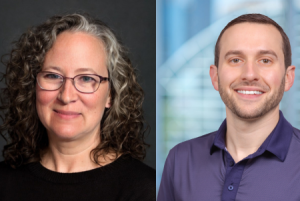

- Embed RFID Tags: Incorporate RFID tags into products for real-time tracking and monitoring,enabling precise location identification at every stage of production.

| Strategy | Benefits |

|---|---|

| Supplier Collaboration | Enhanced visibility and control over the entire supply chain. |

| Data Analytics | Utilize advanced analytics to extract valuable insights and optimize processes. |

Challenges and Solutions for Implementing traceability Measures

Implementing traceability measures in manufacturing comes with its fair share of challenges. One key obstacle is the complexity of supply chains, which can make it difficult to track products from raw materials to the finished goods. additionally, resistance to change within organizations can hinder the adoption of new traceability technologies.

However, there are solutions to these challenges that can help tighten product traceability. Leveraging advanced data analytics tools can streamline the process of tracking products, while investing in employee training can ensure smooth implementation. Collaboration with supply chain partners and the use of blockchain technology can also enhance traceability efforts.

Innovative Technologies for Strengthening Product Traceability

In today’s fast-paced manufacturing landscape, ensuring product traceability is crucial for maintaining quality, compliance, and customer trust. leveraging innovative technologies can significantly enhance traceability processes, enabling manufacturers to track products through every stage of production and distribution.

Here are 6 ways to tighten product traceability in manufacturing:

- Blockchain: Implement blockchain technology to create an immutable ledger of product data, ensuring transparency and security.

- IoT Sensors: Utilize IoT sensors to collect real-time data on product location, temperature, and othre critical parameters.

- QR Codes: incorporate QR codes on product packaging to provide consumers with instant access to detailed product information.

The Role of Data Analytics in improving Traceability Efforts

Data analytics plays a crucial role in improving traceability efforts within manufacturing processes. By harnessing the power of data, companies can enhance their ability to track and monitor products throughout the supply chain, leading to improved efficiency and transparency.

Here are six ways in which data analytics can help tighten product traceability:

- Real-time monitoring: Utilize data analytics to track products in real-time, enabling quick identification of any issues or discrepancies.

- Supply chain visibility: Gain deeper insights into the entire supply chain, ensuring greater transparency and accountability.

- Predictive analytics: Anticipate potential disruptions or quality issues before they occur,allowing for proactive measures to be taken.

- Quality control: implement data-driven quality control processes to maintain high standards and reduce defects.

- Compliance tracking: Use data analytics to ensure compliance with regulations and industry standards, reducing the risk of non-compliance.

- Process optimization: Analyze data to optimize manufacturing processes,leading to increased efficiency and cost savings.

Final Thoughts

enhancing product traceability in manufacturing is crucial for ensuring quality, safety, and compliance standards are met. By implementing the six strategies outlined in this article, companies can tighten their traceability processes and pave the way for greater efficiency and transparency. Innovation and technology play a key role in revolutionizing the way we track and monitor products throughout the supply chain. With a proactive approach and a commitment to continuous enhancement, manufacturers can stay ahead of the curve and establish themselves as industry leaders in the realm of product traceability. Remember, traceability is not just a requirement but a strategic advantage that can drive success in today’s competitive market.