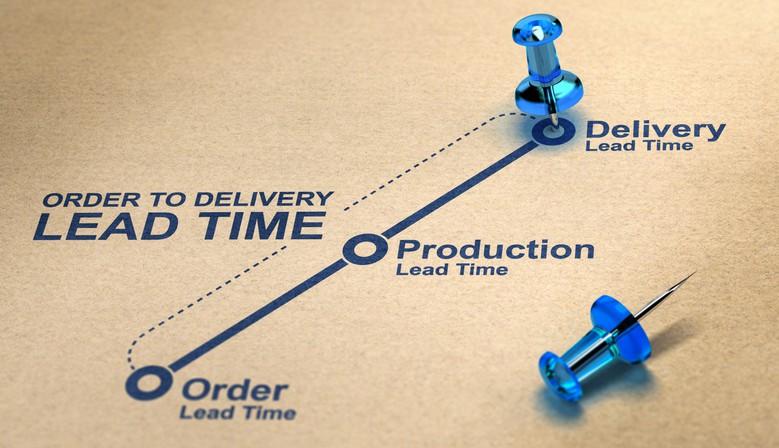

In a harmonious symphony of innovation and precision, MetalQuest orchestrates a transformative journey towards enhanced supply chain efficiency. Embarking on a remarkable collaboration with a manufacturing partner, MetalQuest has achieved a groundbreaking feat, slashing lead times by an astounding 75%. This revolutionary shift paves the way for a new era of streamlined operations and heightened productivity, setting a remarkable precedent in the realm of manufacturing excellence.

– Revolutionizing Supply Chain Dynamics Through MetalQuest Integration

MetalQuest’s integration has revolutionized supply chain dynamics for our manufacturing partner,streamlining processes and enhancing efficiency. By leveraging MetalQuest’s innovative technologies, our partner has successfully slashed lead times by an extraordinary 75%, enabling them to meet customer demands with unprecedented speed.

The seamless integration of MetalQuest has not only optimized production schedules but also improved communication between suppliers and manufacturers. With real-time data sharing and automated workflows, our partner now enjoys smoother operations and enhanced collaboration across the supply chain. This transformative shift has positioned them as a frontrunner in the industry, setting new standards for supply chain management.

– Unveiling the Impact: 75% Reduction in Lead Times Achieved

MetalQuest’s groundbreaking supply chain optimization has led to a remarkable 75% reduction in lead times for its esteemed manufacturing partner. This substantial achievement highlights the company’s unwavering commitment to enhancing operational efficiency and streamlining production processes.

The implementation of innovative methodologies and strategic collaborations has enabled MetalQuest to revolutionize its workflows, resulting in significant time and cost savings for all stakeholders involved. Through meticulous planning, advanced technology integration, and a relentless pursuit of excellence, MetalQuest has set a new industry standard for lead time reduction, empowering its partners to thrive in a competitive market environment.

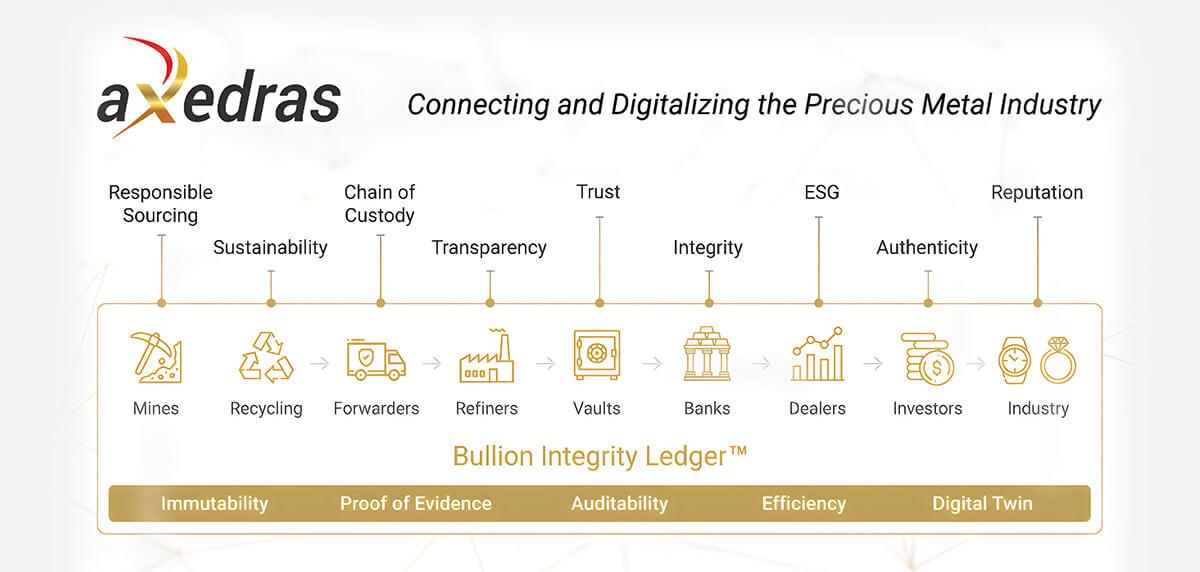

– Streamlining Manufacturing Processes with Cutting-Edge Technology

MetalQuest’s innovative application of cutting-edge technology has revolutionized the way manufacturing processes are carried out, setting a new standard for supply chain efficiency in the industry. By implementing state-of-the-art automation systems and real-time monitoring tools, MetalQuest has successfully slashed lead times by an impressive 75% for their manufacturing partner.

This remarkable achievement not only highlights MetalQuest’s commitment to continuous improvement but also underscores the immense potential of integrating advanced technology into customary manufacturing practices.Through streamlined workflows, optimized resource allocation, and data-driven decision-making, MetalQuest has not only met but exceeded expectations in delivering high-quality products within record timeframes.

– Enhancing Operational Efficiency: Key Takeaways for Industry Optimization

MetalQuest’s innovative approach to supply chain optimization has revolutionized the manufacturing industry, setting a new standard for operational efficiency. By implementing advanced logistics management and streamlining production processes, MetalQuest successfully reduced lead times for its manufacturing partner by an impressive 75%. This remarkable achievement not only enhances overall performance but also underscores the importance of strategic collaboration in driving industry optimization.

One of the key takeaways from MetalQuest’s success story is the significant impact of data-driven decision-making in improving operational performance. By leveraging real-time analytics and predictive modeling,MetalQuest was able to identify bottlenecks,streamline workflows,and enhance resource allocation effectively. This proactive approach not only optimized production schedules but also enabled the manufacturing partner to meet market demands more efficiently. As the industry continues to evolve, MetalQuest’s commitment to operational excellence serves as a guiding light for organizations seeking to maximize their competitive edge through enhanced supply chain efficiency.

In Retrospect

MetalQuest’s innovative approach to supply chain management has not only revolutionized their own manufacturing processes but has also provided significant benefits for their partners. By slashing lead times by 75%, MetalQuest has set a new standard for efficiency in the industry. The success of this partnership exemplifies the power of collaboration and forward-thinking strategies in driving positive change. As MetalQuest continues to shape the future of manufacturing, their commitment to excellence serves as inspiration for all those seeking to unlock new levels of efficiency and productivity in their supply chains.